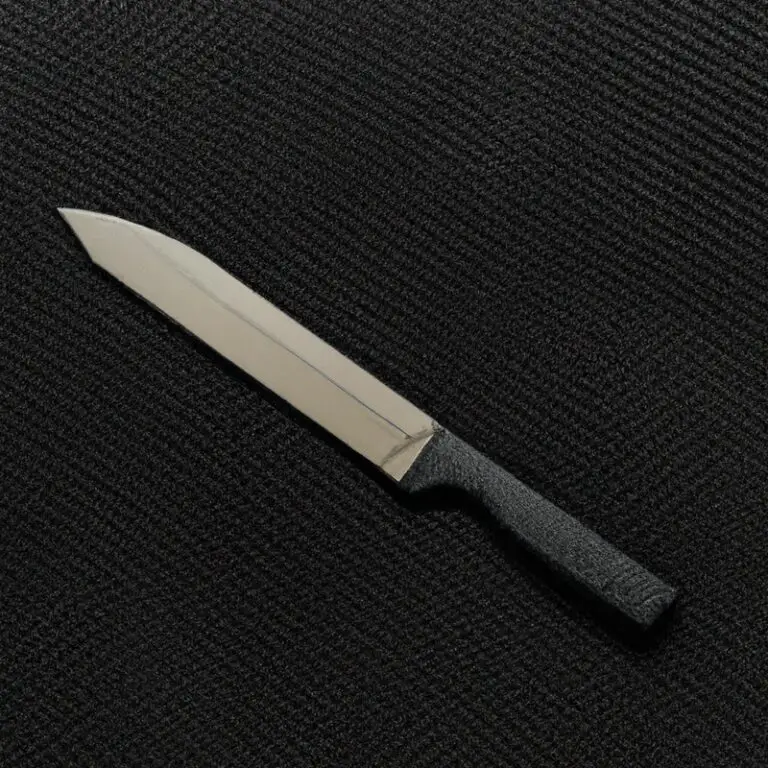

What Are The Characteristics Of a Gyuto Knife That Ensure Durability? Explained

Key Takeaways:

- A Gyuto knife is known for its durability due to its high-quality Japanese steel and sturdy construction.

- A full tang design and reinforced handle provide added strength and stability, enhancing the lifespan of the knife.

- The blade’s hardness and resistance to corrosion also contribute to its longevity, ensuring it retains its sharp edge over time.

- Proper care and maintenance, such as regular sharpening and hand washing, are crucial to preserving a Gyuto knife’s durability and performance.

As an experienced chef, I’ve come across countless knives in my career, but the Gyuto knife remains unmatched in terms of durability. What makes it stand out from other knives?

It’s the combination of several key factors – high-quality steel, blade thickness, handle material, blade shape, hardness level, and more.

In this article, we’ll delve into the characteristics of a Gyuto knife that ensure its durability. From forging vs.

stamping to unique features that boost strength, we’ll cover everything you need to know about this versatile and long-lasting culinary tool.

| Feature | Description |

|---|---|

| Blade Material | The blade is made of high-quality steel that is hard and resistant to wear and tear. |

| Blade Thickness | The blade is thick enough to allow for durability, yet thin enough to make precise cuts. |

| Blade Hardness | The blade is heat-treated and has a Rockwell hardness of around 60-65 HRC, making it strong and durable. |

| Edge Retention | The blade has excellent edge retention, meaning it maintains a sharp edge for longer. |

| Handle Material | The handle is made of durable and water-resistant materials, such as resin or hardwood. |

| Bolster | The bolster is a thick metal band that helps balance the knife and prevents the blade from chipping. |

| Tang | The knife has a full tang, meaning the metal of the blade extends to the end of the handle, making it stronger and more durable. |

High-Quality Steel: The Key to a Durable Gyuto Knife

High-quality steel is a crucial factor in ensuring the durability of Gyuto knives. The blade’s steel determines its resistance to rust, corrosion, and chipping, making it easier to maintain and more long-lasting.

Japanese knives typically use high-carbon steel, which has a higher degree of rigidity, durability, and sharpness, giving them an advantage over other types of steel.

Apart from carbon, other elements like Vanadium, Molybdenum, and Nickel are added to steel to improve its durability even further. The heat treatment process also plays an essential role in improving steel quality, making it harder and more robust.

For a durable Gyuto knife, high-quality steel should be the primary consideration.

The Importance of Blade Thickness in Improving Gyuto Knife Durability

Blade thickness plays a crucial role in determining the durability of a Gyuto knife. Thicker blades are more durable than thin blades as they can withstand more wear and tear.

They are less likely to bend or chip when subjected to tough cutting tasks, making them ideal for use in busy kitchens.

However, excessively thick blades can also compromise cutting performance, making it challenging to cut through dense food items. Therefore, the blade thickness should be within the recommended range for optimal durability and performance.

In summary, choosing a Gyuto knife with the appropriate blade thickness is crucial for durability.

A thicker blade will provide increased durability, while also ensuring optimal performance.

Handle Material: How It Affects Gyuto Knife Longevity

The handle material is a crucial factor in determining the longevity of a Gyuto knife. A durable handle material ensures longevity and enhances the knife’s performance.

The handle material directly affects the knife’s grip, balance, and durability.

High-quality materials such as wood, plastic, and composite materials are commonly used to make Gyuto knife handles. Wood handles provide a comfortable grip and enhance the knife’s aesthetics, but they require proper maintenance to prevent cracking, warping, or splitting.

Plastic and composite handle materials are durable, resistant to moisture, and easy to maintain.

The type of handle construction also affects the knife’s durability. A full-tang handle ensures stability and improves the knife’s balance.

A partial-tang, rat-tail, or hidden-tang handle construction may cause the knife to snap easily after a few uses.

To ensure the best longevity for a Gyuto knife, choose a handle material that suits your needs and preferences. Consider the material’s durability, maintenance requirements, comfort, and grip.

Also, opt for a handle construction that guarantees stability and balance.

With proper care and maintenance, a well-chosen handle material can ensure a long-lasting, high-performance Gyuto knife.

The Role of Blade Shape in Creating a Durable Gyuto Knife

One crucial factor in creating a durable Gyuto knife is the blade shape. A well-designed blade shape plays a significant role in enhancing the knife’s cutting performance and longevity.

The ideal blade shape for a Gyuto knife should have a relatively flat belly, a slightly curved edge, and a pointed tip.

The flat belly provides stability and ensures smooth cutting, while the curved edge allows for effortless rocking motion when slicing through food items. The pointed tip is perfect for intricate cuts, making it an essential feature in any Gyuto knife.

Additionally, a well-designed blade shape helps to distribute the knife’s weight perfectly, making it feel well-balanced in the hand.

This design reduces the strain on the user’s wrist and arm, allowing for long hours of comfortable use without fatigue. In summary, when choosing a Gyuto knife for durability, pay close attention to the blade’s shape.

Look for a sharp, well-balanced blade with a slightly curved edge and a pointed tip to maximize the knife’s performance and longevity.

Hardness Level: How It Influences Gyuto Knife Durability

The hardness level of a Gyuto knife influences its durability. A harder knife will retain its sharpness for longer periods, reducing the need for frequent sharpening, and extending the life of the blade.

The Rockwell Scale is used to measure the hardness level of knives.

Most Gyuto knives have a hardness level between 58-65 HRC, which provides a balance between durability, sharpness, and flexibility. However, the downside of harder blades is that they can be brittle and prone to chipping or cracking if subjected to too much force or impact.

Moreover, harder blades require proper maintenance and care to prevent damage and maintain their durability.

Therefore, it’s important to choose a Gyuto knife with a significant hardness level, but one that is also durable enough to handle everyday use without breaking or chipping.

Maintenance and Care Tips for Ensuring Long-lasting Gyuto Knives

Proper maintenance and care are essential in ensuring the longevity of your Gyuto knife. Here are some tips to help you keep your knife in top condition:

- Clean your knife after every use with warm soapy water and a soft cloth, then dry it thoroughly with a towel.

- Do not use abrasive cleaning tools such as steel wool or scouring pads, as they can scratch the blade’s surface.

- Sharpen your knife regularly to maintain its sharpness. Use a sharpening stone or honing steel to remove any dullness.

- Store your knife in a sheath or blade guard to protect it from damage and keep it away from other knives or utensils.

- Avoid using your knife for tasks that it’s not designed for, such as prying or chopping bones, as this can damage the blade and affect its performance.

Following these simple care tips will help ensure that your Gyuto knife stays sharp and durable for years to come.

Forging vs. Stamping: Which Method Makes the Most Durable Gyuto Knives?

Forging and stamping are two methods used to create Gyuto knives, and they can impact their durability. Forged knives are created by hammering heated metal into shape.

The process aligns the knife’s grain structure, making it stronger and more durable.

However, it is a labor-intensive process that requires skilled artisans. On the other hand, stamped knives are made by cutting the shape of the blade from a sheet of steel.

It is a quicker and more cost-effective process but does not offer the same level of strength and durability as forging.

The stamping process can result in a weaker blade, often prone to chips and cracks. Overall, forged knives tend to be more durable and long-lasting than stamped knives.

However, the quality of the steel, thickness of the blade, and other factors still play a significant role in the knife’s longevity.

It is essential to choose a reputable manufacturer known for using high-quality steel and skilled forging techniques.

Unique Features That Boost Gyuto Knife Durability

Unique Features That Boost Gyuto Knife Durability

- Full Tang Construction: A full tang blade means the metal extends the length of the handle, providing extra stability and strength to the knife. This design prevents the blade from wobbling, breaking, or detaching from the handle.

- Riveted Handles: Riveted handles provide additional durability by attaching the handle to the blade tang with metal pins. This construction prevents the handle from loosening or falling off, prolonging the knife’s lifespan.

- Dimpled Blade Surface: Some Gyuto knives feature dimples on the blade surface, which act as air pockets and prevent food from sticking. On a durability front, these dimples also enhance the knife’s strength by reducing the blade’s surface area that comes into contact with food.

- Protective Coatings: Applying a protective coating, such as a non-stick or scratch-resistant finish, to the blade can improve its durability by preventing damage caused by harsh conditions or misuse. Coatings also make knives easier to clean, extending their longevity.

- Finger Guards and Bolsters: Knives with finger guards and bolsters provide extra protection for the user’s fingers and hands and prevent the blade from breaking down over time. These features provide added stability to the knife’s handle, protecting against breakage.

In summary, several unique features can improve a Gyuto knife’s durability, including full tang construction, riveted handles, dimpled blade surface, protective coatings, and finger guards/bolsters. Additionally, selecting high-quality steel, the right blade thickness, and appropriate hardness level can also enhance the longevity of a Gyuto knife.

How Finger Guards and Bolsters Improve Gyuto Knife Strength and Durability

Finger guards and bolsters play a crucial role in increasing the overall strength and durability of the Gyuto knife. A finger guard helps in preventing finger injuries during usage, ensuring that your fingers are safe.

Bolsters, on the other hand, situates at the juncture of the handle and blade to offer a comfortable grip while using the knife.

They also add stability and balance to the knife, increasing the overall durability. Finger guards and bolsters made of sturdy materials such as stainless steel provide extra reinforcement against wear and tear.

Hence, while purchasing a Gyuto knife, choosing one with a finger guard and bolster will significantly increase its overall strength and durability.

The Influence of Blade Coatings on Gyuto Knife Durability

Blade coatings can have a significant impact on the durability of a Gyuto knife. Certain coatings, such as ceramic and diamond-like carbon, can add an extra layer of protection to the blade surface, making it more resistant to wear and tear.

This means that the blade will remain sharper for longer periods, while also reducing the frequency of sharpening required, which in turn can prolong the lifespan of the knife.

However, it’s important to note that coatings are not a replacement for proper maintenance and care, as a poorly maintained knife can still suffer from rust and corrosion underneath the coating. Overall, a high-quality coating, combined with proper care, can help ensure that a Gyuto knife remains durable and reliable for years to come.

Final Verdict

A high-quality Gyuto knife is a valuable investment for any chef or home cook. The key characteristics that ensure durability are blade thickness, handle material, blade shape, hardness level, forging method, and blade coating.

By selecting a Gyuto knife with these features and maintaining it properly, you can enjoy a long-lasting, reliable kitchen tool that will always perform at its best.

Remember to choose a trustworthy brand that uses high-quality materials and employs skilled craftsmanship. By following these tips, you can confidently select a durable Gyuto knife that will serve you well for years to come.