How Does Knife Steel Influence Blade Hardness?

Key Takeaways:

- Knife steel composition affects blade hardness.

- Higher carbon content results in a harder blade.

- Different knife steels offer varying levels of hardness.

- Heat treatment can also impact blade hardness.

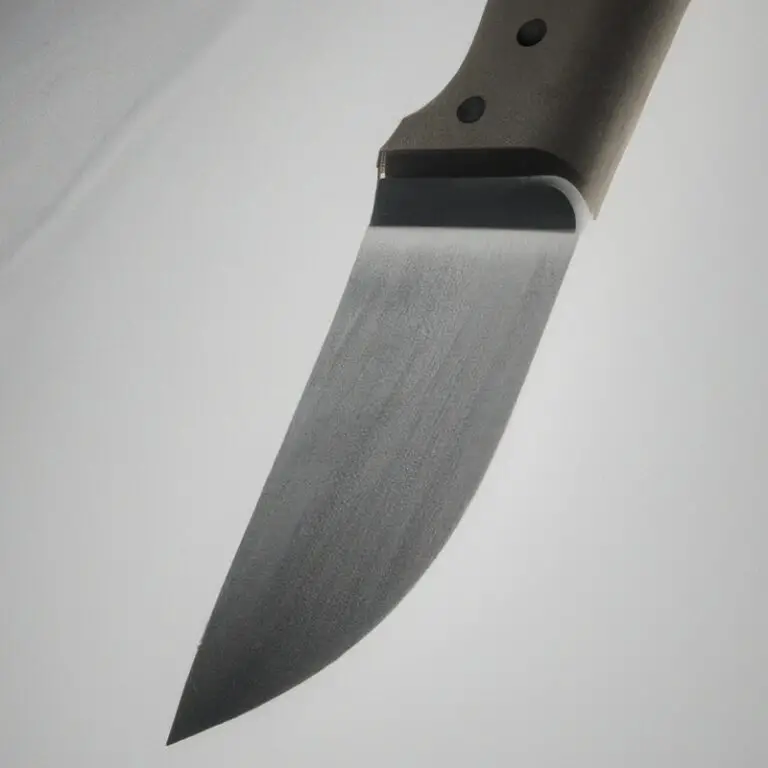

Hey there, knife enthusiasts! Have you ever wondered why some blades are super tough and can hold an edge for what feels like forever, while others seem to dull after just a few uses? Well, let me tell you, it all comes down to one critical factor – knife steel! In this article, I’ll be diving into the fascinating world of knife steel and how it influences blade hardness.

We’ll explore the different types of knife steel, the factors that determine blade hardness, and the impact it has on performance.

So, grab your favorite blade and let’s get sharpening!

| Knife Steel Type | Hardness Level |

| Low Carbon Stainless Steel | 50-55 HRC |

| High Carbon Stainless Steel | 55-60 HRC |

| Tool Steel (e.g. D2, A2) | 58-62 HRC |

| High-Speed Steel (e.g. M2) | 60-65 HRC |

| Carbon Steel (e.g. 1095) | 55-60 HRC |

Knife Steel Types

Stainless Steel

Stainless steel is a popular material for knife blades due to its excellent corrosion resistance.

It contains a minimum of 10.5% chromium, which forms a protective layer on the surface, preventing rust and staining.

Stainless steel blades require less maintenance and are ideal for use in humid or wet conditions.

However, stainless steel does not hold an edge as well as other types of steel and may be more difficult to sharpen.

It’s a great choice for outdoor enthusiasts or everyday kitchen tasks.

Carbon Steel

Carbon steel is a popular choice for knife blades due to its excellent hardness and durability. It is a type of steel that contains a higher percentage of carbon compared to other steels.

This high carbon content increases the hardness of the blade, allowing it to hold a sharp edge for longer periods.

Carbon steel knives are also easier to sharpen, providing the users with a precise cutting tool. However, carbon steel blades are prone to rust and corrosion, so proper care and maintenance are essential.

Regular oiling and drying after use can help prevent rusting.

Tool Steel

Tool steel is a type of steel specifically designed for making tools.

It is known for its high hardness, toughness, and wear resistance.

Tool steel is used to create cutting and shaping tools, such as knives, drills, and chisels, that require good edge retention and durability.

Common types of tool steel include D2, A2, and O1, each with its own unique composition and properties.

The hardness and performance of tool steel can be further enhanced through heat treatment processes like quenching and tempering.

Choosing the right tool steel for your needs depends on the specific requirements of the tool and the desired performance characteristics.

Factors Influencing Blade Hardness

Carbon Content

Carbon content is a significant factor in determining the hardness of a knife blade. The higher the carbon content, the harder the blade will generally be.

This is because carbon strengthens the steel and enables it to retain a sharp edge for longer periods of time.

Blades with lower carbon content may be more flexible, but they may also require more frequent sharpening. It’s important to find the right balance of carbon content for your specific needs and preferences.

Remember, the higher the carbon content, the harder the blade.

Heat Treatment

Heat treatment plays a critical role in determining the hardness and performance of a knife blade. It involves carefully controlling the heating and cooling process to transform the molecular structure of the steel.

This process, known as quenching and tempering, enhances the blade’s hardness, strength, and toughness.

By heating the blade to a specific temperature and then rapidly cooling it, the steel becomes harder. Tempering follows, which reduces the brittleness and increases the overall toughness.

The precise heat treatment can significantly impact the final hardness and performance of the blade.

Alloying Elements

Alloying elements play a significant role in determining the hardness of knife blades. These elements are added to the base metal to enhance specific properties.

For example, chromium increases corrosion resistance, while vanadium improves wear resistance.

Different combinations and amounts of alloying elements can result in varying levels of hardness. It’s essential to understand the impact of these elements on blade performance and choose the right steel for your needs.

Quenching and Tempering

Quenching and tempering are essential steps in the heat treatment process of knife steel.

Quenching involves rapidly cooling the heated blade to increase its hardness.

This is done by immersing the blade in a fluid, such as oil or water.

Tempering is the subsequent step where the blade is reheated to a specific temperature and then cooled slowly.

This process reduces the brittleness caused by quenching, making the blade more durable and resistant to breaking.

Quenching and tempering can significantly impact the final hardness and toughness of a knife blade, making it a vital consideration in the manufacturing process.

Impact of Blade Hardness on Performance

Sharpness and Edge Retention

Sharpness and edge retention are key factors affected by blade hardness. A harder knife steel will typically provide better sharpness and edge retention.

When a blade is harder, it can withstand wear and maintain its sharpness for a longer period of time.

This means that you won’t need to sharpen it as frequently. However, it’s important to note that a harder blade may also be more brittle, making it more prone to chipping or breaking if not used properly.

Ultimately, the balance between hardness and durability depends on your specific needs and preferences.

Durability and Wear Resistance

Durability and wear resistance are important factors to consider when choosing knife steel.

A durable blade is less likely to chip, break, or bend during use, increasing its lifespan.

Wear resistance refers to how well the blade retains its sharpness over time.

High wear resistance means the blade can maintain a sharp edge even after prolonged use.

Factors such as steel composition, heat treatment, and hardness level influence the durability and wear resistance of a knife.

Opting for a steel known for its durability and wear resistance will ensure a longer-lasting and more reliable blade.

Corrosion Resistance

Corrosion resistance is an important factor to consider when choosing a knife steel. It refers to the ability of the steel to withstand rust and corrosion over time.

Stainless steel is known for its excellent corrosion resistance, making it a popular choice for kitchen knives and outdoor tools.

It contains a high percentage of chromium, which forms a protective layer on the surface of the steel, preventing it from reacting with oxygen and moisture in the environment. Carbon steel, on the other hand, is more susceptible to corrosion.

It requires proper maintenance, such as drying the blade after use and applying a thin coat of oil, to prevent rust.

However, some carbon steels are treated with special coatings or alloys to enhance their corrosion resistance. When considering the corrosion resistance of a knife steel, it’s important to think about the environment and intended use of the knife.

If you plan on using the knife in wet or humid conditions, it’s best to choose a steel with a high level of corrosion resistance.

Choosing the Right Knife Steel for Your Needs

Types of Knives and Their Requirements

Different types of knives have specific requirements based on their intended use. For example:

- Chef’s knives: These knives require a balance between sharpness and durability for versatile cutting tasks in the kitchen.

- Fillet knives: Flexibility is crucial for filleting fish, allowing for precise, clean cuts along the bone.

- Hunting knives: Durability and edge retention are important for field dressing game.

- Pocket knives: Portability and versatility are key, with a focus on a sharp edge for everyday tasks.

- Bread knives: Serrated blades are necessary for slicing through crusty bread without crushing it.

Considering the requirements of the specific knife type is essential for choosing the appropriate steel.

Personal Preferences and Skill Level

Your personal preferences and skill level play a crucial role in choosing the right knife steel.

Consider what you value in a knife, such as sharpness, ease of sharpening, or corrosion resistance.

Additionally, think about your skill level in terms of maintaining and sharpening the blade.

Some steels may require more care and expertise to keep them performing at their best.

Ultimately, your personal preferences and skill level will guide you in finding the perfect knife steel that suits your needs and enhances your performance in the kitchen or outdoors.

Cost Considerations

Cost considerations play a significant role in choosing the right knife steel. Different types of knife steel vary in cost, with stainless steel generally being more affordable compared to carbon steel and tool steel.

While stainless steel is budget-friendly, it may not offer the same level of hardness and edge retention as higher-end steels.

Carbon steel and tool steel, on the other hand, tend to be more expensive but provide excellent hardness and durability. Ultimately, it’s important to strike a balance between your budget and desired performance when selecting knife steel.

Final Verdict

Knife steel plays a crucial role in determining the hardness of a blade. Stainless steel offers excellent corrosion resistance but may sacrifice some hardness.

Carbon steel provides exceptional sharpness and edge retention, but may require more maintenance to prevent corrosion.

Tool steel combines high hardness with durability, making it suitable for heavy-duty tasks. Factors such as carbon content, heat treatment, alloying elements, and quenching and tempering techniques all contribute to achieving the desired hardness.

When choosing the right knife steel, consider the specific requirements of your intended use, personal preferences, skill level, and cost considerations.

Trust in the information provided to make an informed decision and enhance your knife performance.