What Are The Properties Of Tool Steel For Knives?

Key Takeaways:

- High hardness and wear resistance make tool steel ideal for knife blades.

- Tool steel offers excellent edge retention, making it suitable for prolonged use.

- Good toughness and corrosion resistance make tool steel knives durable and low-maintenance.

- Proper heat treatment of tool steel can enhance its performance and maximize its potential.

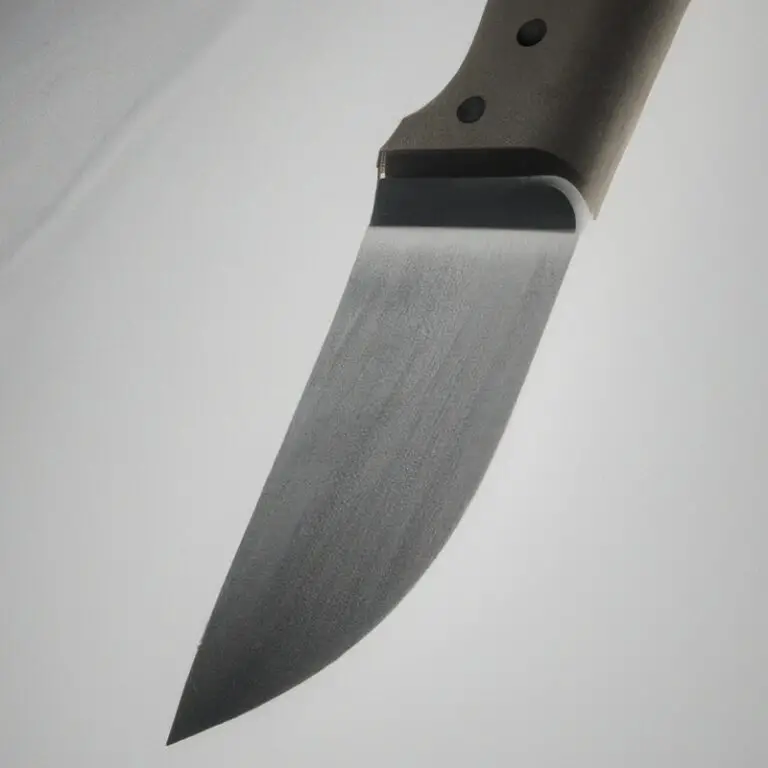

Are you tired of knives that lose their sharpness and fall apart after a few uses? Well, I’ve got great news for you! In the world of cutlery, tool steel is the superhero material that can transform your kitchen or outdoor adventures.

But what exactly is tool steel?

And why is it the perfect choice for crafting durable and reliable knives? In this article, I will dive into the properties of tool steel for knives, exploring its hardness, toughness, wear resistance, and corrosion resistance.

We’ll also explore the different grades of tool steel and their common applications, as well as share some tips on care and maintenance.

Get ready to discover the secret behind long-lasting and high-performing knives!

| Property | Description |

| Hardness | Tool steel for knives is known for its high hardness, typically ranging between 58-65 HRC. This allows the knife to maintain its sharpness even after prolonged use. |

| Toughness | Tool steel is also valued for its toughness, which enables it to withstand high impact and resist breaking or chipping. This makes it suitable for demanding cutting tasks. |

| Corrosion resistance | Some tool steels have relatively high levels of chromium, which enhances their corrosion resistance. However, proper care and maintenance are still required to prevent rusting. |

| Wear resistance | Tool steel exhibits excellent wear resistance, allowing the blade to retain its sharp edge for long periods without significant deterioration. This property helps reduce the frequency of sharpening. |

| Edge retention | Due to its hardness and wear resistance, tool steel knives have excellent edge retention. These knives can maintain a sharp cutting edge even after repetitive use. |

What is Tool Steel?

Definition of Tool Steel

Tool steel is a type of steel specifically designed for making tools.

It has excellent hardness, toughness, and wear resistance, making it well-suited for applications where tools are subjected to high stress and wear.

Tool steel is typically alloyed with elements like chromium, vanadium, and tungsten to enhance its properties.

It is used in various industries, including automotive, aerospace, and manufacturing.

In knives, tool steel is highly valued for its ability to hold a sharp edge and withstand repeated use.

Types of Tool Steel

There are several types of tool steel that are commonly used for knives. Some of the most popular types include:

- High Carbon Tool Steel: This type of tool steel is known for its high hardness and excellent edge retention. It is commonly used in making high-quality chef’s knives and hunting knives. Examples of high carbon tool steel include AISI D2 and AISI O1.

- Stainless Tool Steel: Stainless tool steel contains a higher amount of chromium, which provides excellent corrosion resistance. It is ideal for knives that will be exposed to moisture and humidity, such as kitchen knives. Common examples include AISI 440C and ATS-34.

- Powdered Tool Steel: Powdered tool steel is produced through a process called powder metallurgy, which results in a finer and more uniform grain structure. This type of tool steel offers enhanced strength, wear resistance, and toughness. Popular powdered tool steel options include CPM S30V and CPM 3V.

These are just a few examples of the types of tool steel used for knives. Each type has its own unique properties and advantages, so it’s important to choose the one that best suits your specific needs and preferences.

Use of Tool Steel for Knives

Importance of Tool Steel for Knives

Tool steel is crucial for knives because of its exceptional properties. First and foremost, tool steel is known for its high hardness, which allows the knives to maintain a sharp edge even after prolonged use.

Additionally, tool steel is highly resistant to wear and tear, ensuring durability and longevity for the knives.

Furthermore, tool steel offers excellent toughness, making the knives resistant to chipping or breaking. Lastly, tool steel exhibits good corrosion resistance, preventing the knives from rusting or tarnishing.

These properties make tool steel an ideal choice for crafting high-quality and reliable knives.

Advantages of Using Tool Steel for Knives

Tool steel offers several advantages for knives.

Firstly, it provides exceptional hardness, making the blade capable of maintaining a sharp edge for an extended period of time.

Additionally, tool steel is known for its toughness, ensuring the blade can withstand heavy use without chipping or breaking.

This durability is especially beneficial for knives used in demanding tasks.

Moreover, tool steel exhibits excellent wear resistance, reducing the need for frequent sharpening.

Lastly, tool steel is often corrosion resistant, preventing the blade from rusting or corroding over time.

These advantages make tool steel an excellent choice for high-quality and long-lasting knives.

Properties of Tool Steel for Knives

Hardness

Hardness is a critical property of tool steel for knives. It refers to the steel’s ability to resist deformation and withstand wear.

A high hardness level means the knife will maintain its edge for longer periods, making it more durable.

Tool steel is specifically designed to have excellent hardness, allowing it to retain its sharpness even after extended use. This property ensures that your knife will perform efficiently and effectively, providing you with precise, clean cuts every time.

So, when choosing a knife made of tool steel, keep in mind that hardness is key for long-lasting performance.

Toughness

Toughness is an important property of tool steel for knives. It refers to the ability of the steel to resist breaking or cracking when subjected to impact or force.

A tough tool steel is less likely to chip or deform under stress.

This is particularly crucial for knives, as they are often used for cutting tough materials or performing heavy-duty tasks. A tough knife blade can withstand abuse and maintain its integrity, ensuring longevity and reliability.

Additionally, toughness also contributes to the overall safety of the knife, reducing the risk of accidents caused by blade failure.

Wear Resistance

Wear resistance is a crucial property of tool steel for knives. It refers to the ability of the steel to withstand friction and abrasion without easily wearing down or losing its sharpness.

Tool steel with high wear resistance can retain its edge for longer periods, reducing the need for frequent sharpening.

This property is particularly important for knives used in tasks that involve cutting tough materials or repetitive use. By choosing a tool steel with good wear resistance, you can ensure that your knife remains effective and reliable over time.

So, it’s definitely worth considering when selecting a knife made from tool steel.

Corrosion Resistance

Corrosion resistance is an important property of tool steel for knives.

It refers to the material’s ability to withstand damage caused by chemical reactions with its environment.

Tool steels with high corrosion resistance are less likely to rust or corrode, making them ideal for knives used in wet or humid conditions.

To enhance corrosion resistance, certain stainless tool steels are often utilized.

These steels contain elements such as chromium, which forms a protective oxide layer on the surface of the knife, preventing corrosion.

Proper care and maintenance, including regular cleaning and drying, can also help to preserve the corrosion resistance of tool steel knives.

Different Grades of Tool Steel for Knives

High Carbon Tool Steel

High carbon tool steel is a popular choice for knives due to its exceptional hardness and edge retention capabilities. It contains a higher percentage of carbon, which gives it increased strength and wear resistance.

This type of steel is ideal for tasks that require precision cutting, such as slicing and dicing.

Additionally, high carbon tool steel can be easily sharpened and holds a razor-sharp edge for extended periods of time. However, it is important to note that high carbon tool steel is not as corrosion-resistant as stainless steel, so proper care and maintenance are necessary to prevent rusting.

Stainless Tool Steel

Stainless Tool Steel is a type of tool steel that contains a certain amount of chromium, which gives it excellent resistance to corrosion and staining. This makes it a popular choice for knife blades, as it can withstand exposure to moisture and acidic foods without rusting or tarnishing.

Stainless Tool Steel also offers good hardness and wear resistance, ensuring that the knife maintains its sharp edge for longer periods.

Its combination of corrosion resistance and durability makes it a reliable option for both kitchen and outdoor knives.

Powdered Tool Steel

Powdered tool steel is a type of tool steel that is made from fine particles of steel that have been compressed and sintered together.

This process results in a steel with excellent wear resistance, high hardness, and good toughness.

The powdered form allows for more precise control over the composition and distribution of elements, resulting in improved performance and consistency.

Powdered tool steel is used in a variety of applications, including knife making, where its superior properties make it an ideal choice for sharp and durable blades.

Common Applications of Tool Steel for Knives

Chef’s Knives

Chef’s knives are a popular application of tool steel. These versatile knives are essential for professional chefs and home cooks alike.

The properties of tool steel make it an excellent choice for chef’s knives.

Tool steel provides high hardness, allowing the knife to hold a sharp edge for longer. It also offers toughness, allowing the knife to withstand heavy use and resist chipping.

Additionally, tool steel provides excellent wear resistance, ensuring the knife stays sharp for extended periods.

Overall, chef’s knives made from tool steel are durable, reliable, and an indispensable tool in any kitchen.

Hunting Knives

Hunting knives are a popular tool among outdoor enthusiasts and hunters.

These knives are specifically designed for tasks like field dressing game, cutting through tough materials, and general utility.

The properties of tool steel make it an excellent choice for hunting knives due to its hardness, toughness, and resistance to wear and corrosion.

Tool steel hunting knives are known for their durability and ability to maintain a sharp edge even after heavy use.

Whether you’re a seasoned hunter or a beginner, a reliable tool steel hunting knife is an essential companion in the field.

Pocket Knives

Pocket knives are incredibly versatile tools that can be used for a variety of everyday tasks. Made from tool steel, pocket knives offer durability, strength, and excellent cutting performance.

They are designed to be compact and easy to carry, making them perfect for use on the go.

Whether you need to open packages, cut rope, or perform small repairs, a pocket knife is a reliable tool to have in your pocket. With proper care and maintenance, a quality pocket knife made from tool steel can last for a long time, ensuring that you always have a handy tool at your disposal.

Care and Maintenance of Tool Steel Knives

Proper Cleaning Methods

To keep your tool steel knives in top condition, proper cleaning methods are essential.

Here are some straightforward steps to follow:

- Rinse after use: After using your knife, promptly rinse it with warm, soapy water. This helps remove any food particles or residue.

- Hand wash: Avoid placing your tool steel knives in the dishwasher. Instead, hand wash them with mild dish soap and a soft sponge or cloth. This reduces the risk of damaging the blade or handle.

- Dry thoroughly: After washing, be sure to dry your knives thoroughly. Tool steel is prone to rusting, so eliminating any moisture is crucial. Use a clean towel to dry them completely.

- Store properly: Store your tool steel knives in a dry and safe place, ideally in a knife block or sheath. Avoid keeping them in damp environments to prevent corrosion.

Sharpening Techniques

When it comes to sharpening tool steel knives, there are a few techniques you can use to maintain their sharpness.

One method is using a sharpening stone, which can help you remove any dullness or nicks from the blade.

Another technique is using a honing rod, which can realign the edge of the knife and keep it sharp.

Additionally, you can also use a sharpening system or a professional sharpening service for more intricate sharpening needs.

Remember to follow the manufacturer’s instructions and take your time to ensure a proper sharpening technique.

Final Verdict

Tool steel is a crucial material for knives due to its exceptional properties.

It offers a perfect balance of hardness, toughness, wear resistance, and corrosion resistance, making it ideal for various cutting applications.

Different grades of tool steel, such as high carbon, stainless, and powdered tool steel, provide specific advantages based on their composition.

Tool steel knives find common use in chef’s knives, hunting knives, and pocket knives.

To maintain their performance, proper cleaning methods and sharpening techniques must be employed.

Overall, tool steel is a reliable and durable option for crafting high-quality knives.