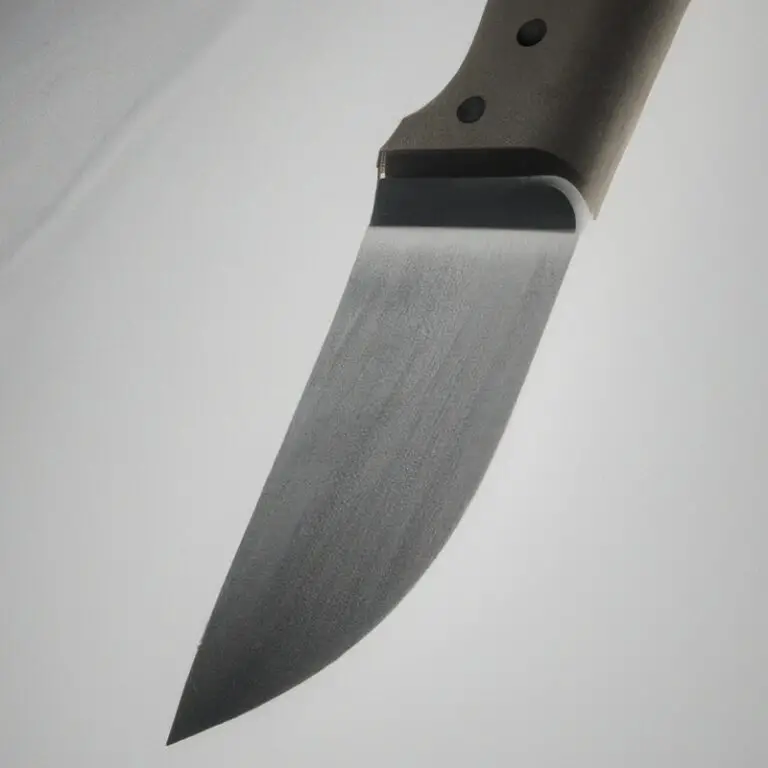

What Is The Effect Of Tungsten In Knife Steel?

Key Takeaways:

- Tungsten enhances the hardness and wear resistance of knife steel.

- Tungsten improves the cutting performance and edge retention of knives.

- Tungsten contributes to improved strength and durability of knife blades.

- Tungsten may increase the cost of knife steel production, but it offers significant benefits in terms of performance and longevity.

Have you ever wondered why some knives seem to maintain their sharpness longer than others? The secret lies in the composition of the steel used to make the blade.

One particular element, tungsten, plays a crucial role in enhancing the performance of knife steel.

With its impressive properties, tungsten brings increased hardness, wear resistance, and improved edge retention to the table. But that’s not all – it also adds a touch of toughness and durability.

In this article, I’ll dive deep into the effects of tungsten in knife steel, its benefits, and what to consider when choosing tungsten-enriched blades.

So, buckle up and get ready to discover the fascinating world of tungsten-infused knives.

| Effect of Tungsten in Knife Steel | |

|---|---|

| Property/Aspect | Effect of Tungsten |

| Hardness | Increases hardness and wear resistance |

| Toughness | Improves toughness and strength |

| Edge Retention | Enhances edge retention and sharpness |

| Corrosion Resistance | No impact on corrosion resistance |

| Grain Structure | Refines the grain structure |

| Functionality | Improves cutting performance and overall functionality |

What is Tungsten?

Properties of Tungsten

Tungsten has some unique properties that make it a valuable element in various applications. First of all, it has an extremely high melting point, making it ideal for use in high-temperature environments.

Tungsten is also very dense, which gives it excellent strength and durability.

Additionally, it has a low coefficient of thermal expansion, meaning it doesn’t expand or contract much with changes in temperature. These properties make tungsten highly desirable for use in industries such as aerospace, electronics, and even in the production of high-quality knife steel.

Tungsten in Knife Steel

Role of Tungsten in Knife Steel

Tungsten plays a significant role in knife steel, bringing several benefits to the final product. It is added as an alloying element to improve hardness, wear resistance, and edge retention.

Tungsten also enhances the toughness and durability of the steel, making it more resistant to chipping and breaking.

Moreover, the presence of tungsten can positively influence the corrosion resistance of the knife steel. The appropriate tungsten content in knife steel is carefully balanced with other alloying elements to optimize performance.

Additionally, tungsten-enriched knife steels may have different sharpening requirements compared to steels without tungsten.

Benefits of Tungsten in Knife Steel

Tungsten offers several benefits when incorporated into knife steel.

Firstly, it significantly increases the hardness and wear resistance of the blade, making it more durable and long-lasting.

Secondly, tungsten improves edge retention, allowing the blade to maintain its sharpness for extended periods.

Additionally, tungsten enhances the toughness of the steel, making the knife less prone to chipping or breaking during use.

Moreover, tungsten can improve the corrosion resistance of the blade, ensuring it remains resistant to rust and staining.

These advantages make tungsten a valuable addition to knife steel formulations.

Tungsten Content in Various Knife Steels

The tungsten content in various knife steels can vary depending on the specific steel composition.

Some knife steels may have a higher tungsten content, while others may have lower or even negligible amounts.

Tungsten is typically added to knife steels to enhance their hardness, wear resistance, and edge retention.

It is worth noting that different knife manufacturers and steel producers may have their own proprietary steel formulations, so the tungsten content can vary from brand to brand.

It is important to consult the specific product information or contact the manufacturer to determine the tungsten content in a particular knife steel.

Effects of Tungsten in Knife Steel

Increased Hardness and Wear Resistance

Tungsten plays a crucial role in increasing the hardness and wear resistance of knife steel.

It forms hard carbides, enhancing the steel’s overall hardness.

This makes the blade less prone to deformation, improving its durability and longevity.

Tungsten also improves wear resistance, reducing the amount of material lost during use.

This means the blade will maintain its sharpness for a longer period, reducing the need for frequent sharpening and ensuring better performance over time.

The presence of tungsten in knife steel greatly enhances its hardness and wear resistance, making it a desirable choice for high-quality knives.

Improved Edge Retention

Improved edge retention is one of the key benefits of tungsten in knife steel.

Tungsten enhances the steel’s ability to retain a sharp edge for longer periods of time, reducing the need for frequent sharpening.

By increasing the hardness and wear resistance of the steel, tungsten helps the blade maintain its cutting performance, even under demanding conditions.

This means that knives made with tungsten-enriched steel can stay sharper and perform effectively for extended periods, making them a great choice for tasks that require long-lasting sharpness.

Enhanced Toughness and Durability

Tungsten plays a significant role in enhancing the toughness and durability of knife steel. Its addition to the steel composition improves the overall strength of the blade, making it more resistant to chipping and breaking.

Tungsten also helps increase the steel’s ability to withstand high temperatures, ensuring that the blade retains its structural integrity even under extreme conditions.

Additionally, the presence of tungsten enhances the wear resistance of the knife, allowing it to maintain its sharpness and durability for longer periods of time. Overall, tungsten-enriched knife steels offer excellent toughness and durability, making them ideal for demanding tasks and prolonged use.

Impact on Corrosion Resistance

The presence of tungsten in knife steel can greatly enhance its corrosion resistance. Tungsten forms carbides that help to strengthen the steel matrix and protect it from chemical reactions with moisture and other corrosive agents.

This means that knives made with tungsten-enriched steel are less likely to rust or corrode over time.

Tungsten also improves the overall durability of the blade, making it a valuable addition to knife steel formulations. So, knives with higher tungsten content are usually more resistant to corrosion, making them ideal for outdoor and marine environments.

Considerations when Choosing Tungsten-Enriched Knife Steels

Tungsten Percentage and Blade Performance

The percentage of tungsten in knife steel directly affects its performance. Higher tungsten content increases hardness, wear resistance, and edge retention.

However, too much tungsten can make the steel brittle.

It’s important to find the right balance based on your intended use for the knife. Different knife steels have varying tungsten percentages, so consider your priorities when choosing the right one.

Remember, tungsten is just one factor in blade performance, so it’s important to consider other aspects like steel composition and heat treatment as well.

Balancing Tungsten with Other Alloying Elements

When it comes to balancing tungsten with other alloying elements in knife steel, it’s important to consider the desired properties of the blade. Tungsten can enhance hardness, wear resistance, and edge retention, but it needs to be balanced with other elements like chromium and carbon.

Adding chromium can improve corrosion resistance, while carbon helps with overall toughness.

It’s crucial to find the right combination of elements to achieve the desired performance and durability of the knife. By experimenting with different alloying elements, knife manufacturers can create blades that excel in specific applications, such as cooking or outdoor activities.

Tungsten’s Influence on Blade Sharpening

Tungsten in knife steel plays a significant role in blade sharpening. Its high hardness and wear resistance contribute to a longer lasting edge, reducing the frequency of sharpening.

Tungsten-enriched steels also tend to have excellent edge retention, allowing the blade to maintain its sharpness for a longer period.

While tungsten does not directly affect the sharpening process itself, its presence in the steel greatly impacts the time and effort required to maintain a sharp edge. Ultimately, knives made with tungsten-enriched steel offer the advantage of extended sharpness and reduced sharpening needs.

Final Verdict

The addition of tungsten in knife steel brings numerous benefits that make it a valuable element in the manufacturing process.

Tungsten enhances hardness, wear resistance, edge retention, toughness, and durability of knives.

It also plays a crucial role in balancing other alloying elements and influences blade sharpening.

The amount of tungsten used in knife steel directly affects its performance, and careful consideration should be given to finding the right balance for each specific knife application.

Tungsten-enriched knife steels offer superior performance and longevity, making them an excellent choice for professionals and enthusiasts alike.