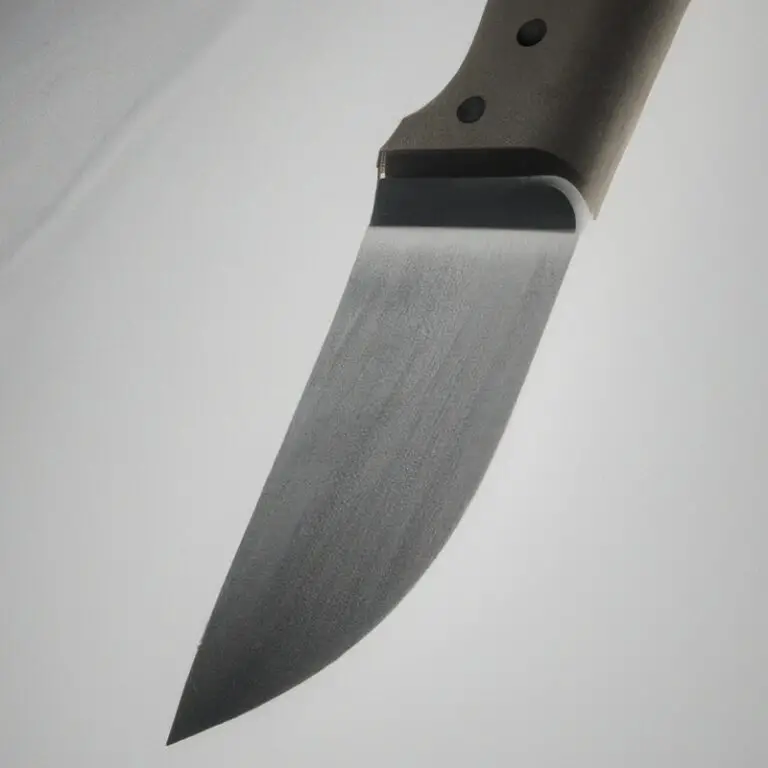

What Are The Disadvantages Of High-Carbon Knife Steel?

Key Takeaways:

- High-carbon knife steel tends to be more prone to rust and corrosion.

- It requires more frequent maintenance and sharpening compared to other types of knife steel.

- High-carbon steel can be more brittle, making it more susceptible to chipping or breaking.

- It may have a higher price point compared to other knife steel options.

Are you a culinary enthusiast who appreciates the art of a perfectly sliced tomato or the precision of a finely diced onion?

If so, you’re likely well-acquainted with the importance of a good knife.

High-carbon steel has long been hailed as the gold standard for professional chefs and avid home cooks alike.

But is it all it’s cracked up to be?

In this article, I’ll delve into the dark side of high-carbon knife steel, from its susceptibility to rust and corrosion to the challenges of maintenance and sharpening.

We’ll also explore alternatives and offer tips to mitigate these disadvantages.

So, grab your favorite kitchen utensil and let’s dig in!

| Disadvantages of High-Carbon Knife Steel |

|---|

| 1. High Maintenance |

| 2. Prone to Rusting and Corrosion |

| 3. Brittle and Less Durable |

| 4. Difficult to Sharpen |

Disadvantages of high-carbon knife steel

High susceptibility to rust and corrosion

High-carbon knife steel is highly susceptible to rust and corrosion due to its composition. The high carbon content makes the steel more prone to oxidization when exposed to moisture and acidic substances.

This can lead to unsightly stains, pitting, and even the degradation of the blade over time.

To prevent rust and corrosion, it is essential to maintain proper care and maintenance of the knife, such as regular cleaning, drying, and oiling. Storing the knife in a dry environment and using a protective sheath or case can also help minimize the risk of rust formation.

Requires frequent maintenance and care

High-carbon knife steel requires frequent maintenance and care. This is because high-carbon steel is more prone to rust and corrosion compared to other types of knife steel.

To keep your high-carbon steel knives in good condition, it is important to regularly clean and dry them after each use.

Additionally, proper storage away from moisture is essential. It is also necessary to regularly hone and sharpen high-carbon steel knives to maintain their sharpness.

Taking these steps will ensure the longevity and performance of your high-carbon steel knives.

More difficult to sharpen and maintain sharpness

One disadvantage of high-carbon knife steel is that it can be more difficult to sharpen and maintain sharpness compared to other types of knife steel.

This is because high-carbon steel is typically harder and more resistant to wear, which means it requires additional effort and skill to bring back its sharp edge.

Regular maintenance, such as honing and sharpening, will be necessary to keep the knife performing at its best.

Additionally, inexperienced sharpening techniques or using the wrong tools can potentially damage the blade, making it even more challenging to achieve a sharp edge.

Prone to chipping and breaking

High-carbon knife steel has a significant disadvantage of being prone to chipping and breaking.

This is because the high carbon content makes the steel harder, but also more brittle.

If the knife is subjected to excessive force or used on hard materials, it can easily chip or even snap.

It is important to use these knives with care and avoid tasks that may cause excessive stress on the blade.

Regular maintenance and proper cutting techniques can help mitigate the risk of chipping and breaking.

Can impart metallic taste to certain foods

High-carbon knife steel, while known for its durability and sharpness, can have the drawback of imparting a metallic taste to certain foods. This is because the high carbon content in the steel can react with certain acidic or alkaline substances found in ingredients like citrus fruits, tomatoes, or vinegar.

As a result, it may alter the taste of the food being prepared or sliced.

To avoid this issue, it’s recommended to use stainless steel or ceramic knives when working with foods that are more prone to metallic taste absorption.

Comparisons to other knife steels

Low-carbon stainless steel

Low-carbon stainless steel is a type of steel that contains a lower percentage of carbon compared to high-carbon steel. This makes it more resistant to rust and corrosion.

Additionally, it is easier to sharpen and maintain sharpness, and it is less prone to chipping and breaking.

However, it may not hold its edge as well as high-carbon steel. Overall, low-carbon stainless steel is a good option for those looking for a durable and low-maintenance knife.

High-carbon stainless steel

High-carbon stainless steel is a popular choice for kitchen knives due to its combination of hardness and corrosion resistance. It contains a higher percentage of carbon than other stainless steels, which improves edge retention and sharpness.

However, high-carbon stainless steel is still susceptible to rust and requires regular maintenance.

It can be more challenging to sharpen and is prone to chipping and breaking. Additionally, some people have reported a metallic taste in certain foods when using high-carbon stainless steel knives.

Damascus steel

Damascus steel is a type of high-carbon steel known for its strength and unique aesthetic appeal.

It is made by layering and forging various grades of steel together, resulting in a distinctive pattern on the blade.

One advantage of Damascus steel is its ability to hold a sharp edge for a long time.

Additionally, the layering process creates a natural resistance to rust and corrosion.

However, Damascus steel can be more expensive and difficult to find compared to other knife steels.

It may also require more frequent maintenance and care to prevent rusting.

Overall, Damascus steel is valued for its durability and beauty.

Tips for mitigating the disadvantages

Regular cleaning and drying

Regular cleaning and drying is essential for maintaining high-carbon knife steel.

After each use, it’s important to wash the knife with warm soapy water and dry it thoroughly with a clean towel.

Avoid leaving the knife wet or submerged in water, as this can lead to rust and corrosion.

Additionally, make sure to clean the knife handle and bolster to prevent dirt and debris buildup.

Regular cleaning and drying will help extend the lifespan of your high-carbon knife steel and keep it in optimal condition.

Proper storage to avoid contact with moisture

To properly store high-carbon knife steel and prevent contact with moisture, you’ll need to take a few simple steps. Firstly, make sure your knives are clean and completely dry before storage.

Secondly, avoid storing them in humid environments, such as a damp kitchen drawer or near the sink.

Thirdly, consider using a knife block or a magnetic strip to keep your knives safely stored and away from moisture. Proper storage is essential to protect your high-carbon knife steel from rust and corrosion, ensuring its longevity and performance.

Regular honing and sharpening

Regular honing and sharpening are essential for maintaining the performance and longevity of high-carbon knife steel. By honing your knife regularly with a honing rod, you can realign the blade’s edge and keep it sharp.

Sharpening, on the other hand, involves removing small amounts of metal to restore the blade’s sharpness.

This can be done using sharpening stones or electric sharpeners. By incorporating regular honing and sharpening into your knife care routine, you can ensure that your high-carbon knife steel stays sharp, cutting smoothly and effectively.

Avoiding excessive force while cutting

To avoid applying excessive force while cutting with a high-carbon steel knife, it’s important to use proper cutting techniques.

Here are a few tips:

- Let the knife do the work: Avoid applying unnecessary pressure and let the sharpness of the blade do the cutting.

- Maintain a steady grip: Hold the knife with a firm but relaxed grip to maintain control and avoid exerting excessive force.

- Use a cutting board: Use a cutting board made of a softer material, such as wood or plastic, to cushion the blade and minimize the impact on the edge.

- Choose the right knife for the task: Select a knife that is suitable for the cutting task at hand to minimize the need for excessive force.

Using a cutting board made of softer material

Using a cutting board made of softer material is a helpful way to mitigate some of the disadvantages of high-carbon knife steel.

A softer material, like wood or plastic, can provide a gentler surface for your knife blade, reducing the risk of chipping or breaking.

Additionally, a softer cutting board is less likely to dull your knife quickly, allowing you to maintain its sharpness for longer periods.

Investing in a cutting board made of a softer material can help prolong the life of your high-carbon steel knives and enhance their performance.

Final Verdict

High-carbon knife steel may offer exceptional sharpness and edge retention, but it does come with its fair share of drawbacks. The susceptibility to rust and corrosion, the need for frequent maintenance, the difficulty in sharpening and the risk of chipping or breaking are all factors that can diminish the overall performance and lifespan of the knife.

Additionally, the potential to impart a metallic taste to certain foods is not ideal for culinary enthusiasts.

However, with proper care, maintenance, and usage techniques, these disadvantages can be mitigated to a great extent, allowing for the full potential of high-carbon knife steel to be realized.