What Are The Properties Of Laminated Steel For Knives?

Key Takeaways:

- Laminated steel for knives offers superior strength and durability due to its layered construction.

- The combination of different steel types in laminated steel enhances the knife’s performance and resistance to wear.

- Laminated steel allows for a sharp and well-defined edge, making it ideal for precision cutting tasks.

- The layered structure of laminated steel also provides better resistance against corrosion and rust, increasing the lifespan of the knife.

Are you a cooking enthusiast looking to elevate your knife skills? Or perhaps an outdoor adventurer in need of a durable blade?

If so, then you’ll want to know about the incredible properties of laminated steel for knives.

Don’t worry if you’re new to the concept—I’ve got you covered. In this article, I’ll walk you through what laminated steel is, how it’s made, and why it’s the ultimate choice for knife enthusiasts.

From its exceptional strength and sharpness to its rust-resistant nature, laminated steel offers a host of advantages that will surely revolutionize your cutting experience.

So, let’s dive in and discover the secrets behind this incredible material!

| Properties | Description |

|---|---|

| Durability | Laminated steel knives are known for their exceptional durability. The layering of different steel types increases the overall strength and toughness of the blade. |

| Sharpness | Laminated steel allows for a very sharp edge to be achieved. The different types of steel used in the lamination process have different hardness levels, resulting in a blade that is both sharp and long-lasting. |

| Resilience | The layering of steel in laminated blades enhances resilience, meaning the blade is more resistant to bending or breaking under pressure. This makes them suitable for heavy-duty tasks. |

| Corrosion Resistance | Some laminated steel knives are made with stainless steel as one of the layers, providing a good level of corrosion resistance. However, it is important to note that this may vary depending on the specific composition and maintenance of the knife. |

| Flexibility | Laminated steel knives offer a balance between hardness and flexibility. The layering process allows for a blade that is rigid enough for precise cutting but still has some degree of flexibility to resist chipping or snapping. |

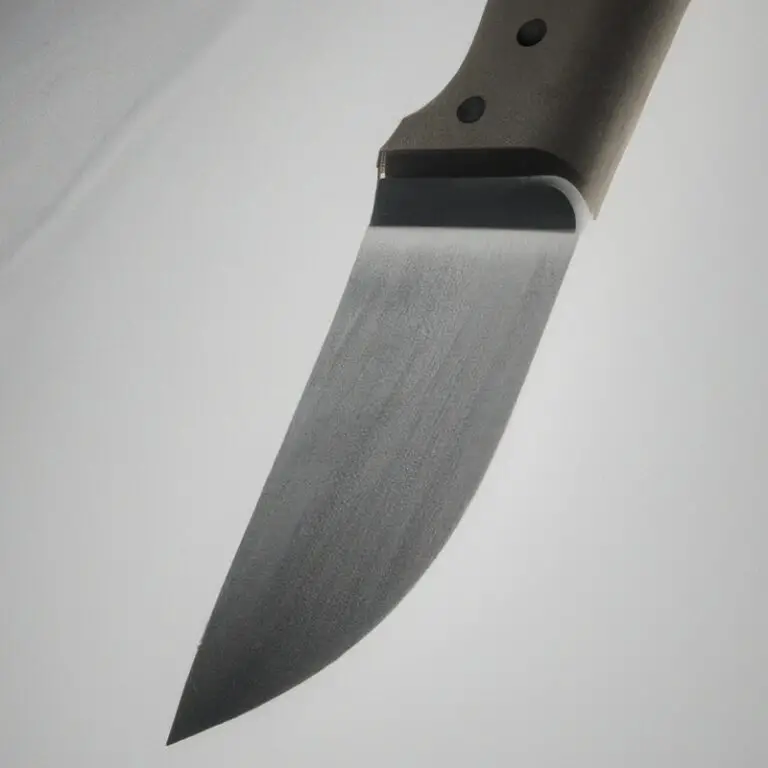

What is laminated steel?

Definition of laminated steel

Laminated steel is a type of steel that is made up of multiple layers or “laminations” of different types of steel. These layers are fused together through a process called welding or forging.

The purpose of using laminated steel is to combine the desirable properties of different types of steel into one material.

This allows for a blade that has superior strength, durability, sharpness, edge retention, and resistance to rust and corrosion. Additionally, laminated steel can also offer flexibility and toughness.

How is laminated steel made?

Laminated steel is made by layering different types of steel together and then forging them into a solid piece. This process involves heating the layers of steel until they are malleable and then using intense pressure to bond them together.

The result is a strong and durable material that combines the desirable properties of each individual steel type.

By using different steels with varying hardness and toughness, laminated steel can be customized to create blades with superior strength, sharpness, and flexibility. This technique has been used for centuries in the production of high-quality knives.

Properties of laminated steel for knives

Strength and durability of laminated steel

Laminated steel is known for its exceptional strength and durability, making it an excellent choice for knives.

The layering process creates a material that is resistant to chipping, breaking, and bending.

This means that laminated steel knives can withstand heavy use and have a longer lifespan compared to other types of steel.

The combination of different steel types in the layers also enhances its overall durability, ensuring that the blade holds up well over time.

Additionally, laminated steel knives retain their sharpness for longer periods, further contributing to their durability.

Sharpness and edge retention of laminated steel

Laminated steel is known for its exceptional sharpness and edge retention, making it a popular choice for knife blades. The layering process involves combining different types of steel, each with its unique properties.

This creates a blade that is both hard and tough, allowing it to maintain its sharpness for extended periods.

The high-carbon steel used in laminated steel provides excellent cutting performance, while the softer layers provide durability and flexibility. The resulting edge is sharp and can withstand rigorous use, making it an excellent option for those who require long-lasting sharpness in their knives.

Rust and corrosion resistance of laminated steel

Laminated steel is known for its exceptional rust and corrosion resistance. The combination of different steel layers creates a barrier against moisture, preventing the formation of rust.

This makes laminated steel knives ideal for use in wet and humid environments.

Additionally, the outer layer of laminated steel can be made from stainless steel, further enhancing its resistance to corrosion. With proper care and maintenance, laminated steel knives can withstand the test of time and remain free from rust and corrosion.

Flexibility and toughness of laminated steel

Laminated steel offers excellent flexibility and toughness, making it a desirable choice for knives. The layering of different steel types creates a blade with a resilient and durable core, capable of withstanding impact and bending without breaking.

This flexibility allows for easier cutting and reduces the risk of chipping or snapping the blade.

Additionally, the toughness of laminated steel ensures that the blade can withstand heavy use and maintain its sharpness over time. Overall, the combination of flexibility and toughness makes laminated steel knives a reliable and long-lasting tool for various applications.

Advantages of using laminated steel for knives

Enhanced performance and cutting ability

Laminated steel for knives offers enhanced performance and cutting ability that sets it apart from other types of steel.

The layering process creates a blade with a hard, sharp edge and a more flexible core, resulting in improved cutting efficiency and reduced risk of chipping or breaking.

This combination allows for precise and controlled slicing, making it a preferred choice for professional chefs and avid cooks alike.

Additionally, the layering process can include different types of steel, each with its own unique properties, further enhancing the performance and versatility of the blade.

Customizable blade properties

Laminated steel offers the advantage of customizable blade properties.

This means that knife makers can choose different types of steel for different layers of the blade, allowing them to create a blade with specific characteristics.

For example, a knife can have a hard steel core for sharpness and edge retention, while softer steel layers provide flexibility and toughness.

This customization allows for a balance of desired qualities in a knife, catering to individual preferences and specific tasks.

Traditional and aesthetic appeal

Laminated steel knives not only offer exceptional performance, but they also have a traditional and aesthetic appeal that many knife enthusiasts appreciate. The layered construction of laminated steel creates a beautiful pattern on the blade, often referred to as a “damascus” or “pattern-welded” design.

This unique and visually striking pattern adds a touch of elegance and artistry to the knife.

Whether displayed in a collection or used in everyday tasks, laminated steel knives are sure to catch the eye and evoke a sense of craftsmanship and history.

Potential for multiple steel types in one blade

One of the advantages of using laminated steel for knives is the potential for multiple steel types in one blade.

This means that different types of steel can be combined to create a blade that offers the benefits of each steel type.

For example, a knife could have a hard steel core for sharpness and edge retention, surrounded by softer steel layers for durability and flexibility.

This allows for a versatile blade that excels in various cutting tasks.

The combination of different steel types also adds complexity and uniqueness to the blade, making it stand out aesthetically.

Popular uses of laminated steel knives

Chef knives and culinary applications

Chef knives made with laminated steel are highly sought after in the culinary world due to their exceptional performance and durability.

The properties of laminated steel, such as its strength, sharpness, and rust resistance, make it perfect for kitchen applications.

These knives provide precise cutting, excellent edge retention, and ease of sharpening, allowing chefs to create perfectly sliced ingredients.

The customizable blade properties of laminated steel also enable chefs to tailor the knife to their specific cutting needs.

So, whether you’re a professional chef or a home cook, laminated steel chef knives are a fantastic choice for all your culinary endeavors.

Hunting and outdoor activities

Hunting and outdoor activities are popular uses for laminated steel knives.

The strength and durability of laminated steel make it ideal for withstanding the rigors of outdoor use.

Whether you’re field dressing game or preparing firewood, laminated steel knives can handle the task.

Additionally, the sharpness and edge retention of laminated steel ensure that your knife stays sharp even after extended use.

Its rust and corrosion resistance also make it suitable for outdoor environments where exposure to moisture is common.

Laminated steel knives provide reliability and performance, making them a great choice for hunters and outdoor enthusiasts.

Collectible and decorative knives

Collectible and decorative knives are highly sought after by knife enthusiasts and collectors. These knives are often made with laminated steel blades, which not only provide exceptional performance but also add to their aesthetic appeal.

The unique patterns and textures created by the layering of different steel types make each knife a work of art.

Collectible and decorative knives are often displayed as part of a collection or used as statement pieces in home decor. They showcase the craftsmanship of the knife maker and are cherished by those who appreciate the beauty and historical significance of these unique blades.

Care and maintenance of laminated steel knives

Proper cleaning and drying techniques

Proper cleaning and drying techniques are essential for maintaining the performance and longevity of laminated steel knives. When cleaning the blade, I recommend using warm water and mild dish soap.

Gently scrub the blade with a soft cloth or sponge, taking care to remove any food particles or stains.

Avoid using abrasive cleaners or scrub brushes, as they can damage the laminated layers. After cleaning, thoroughly dry the knife with a towel to prevent moisture from causing rust or corrosion.

Additionally, it’s important to store the knife in a dry place to further protect it from moisture damage.

Regular sharpening and honing

Regular sharpening and honing are vital for maintaining the performance of laminated steel knives. Sharpening removes any dullness from the blade edge, while honing realigns the microscopic teeth on the edge to maintain sharpness.

To sharpen, you can use a whetstone or a sharpening system.

Start with a coarse grit and gradually work your way to a finer grit for a polished edge. Honing can be done with a honing rod or a leather strop.

Regularly sharpening and honing your laminated steel knife will ensure that it stays sharp and ready for use.

Final Verdict

Laminated steel offers a range of desirable properties that make it an excellent choice for knife blades. Its strength, durability, and sharpness retention ensure long-lasting performance, while its rust and corrosion resistance make it suitable for various environments.

Additionally, the flexibility and toughness of laminated steel allow for precise cutting and resistance to chipping.

The advantages of using laminated steel for knives include enhanced performance, customization options, and a traditional aesthetic appeal. Popular uses include culinary applications, hunting, and collectible knives.

Proper care and maintenance, such as regular sharpening and protection against rust, will ensure the longevity of laminated steel knives.

Overall, laminated steel is a reliable and versatile material that elevates the performance and durability of knives.